Containers

- Container or cap feed as bulk goods via fully automatic sorting and optional storage bin

- Container classification via the infeed screw

- Container transport using pucks for flexible production and fast conversion

- Continuous container transport

- Optimized container transport for preventing splashing in little headroom

- Very gentle processing of the containers

- Processing different container shapes

Shapes

- User-friendly, fast and primarily tool-free format change

Design

- Can be designed as a monobloc combination with filling and sealing modules

- Good visibility and accessibility

- Integrated separation for reject product and/or production patterns

- Compact design with low space requirement

- Min./max. Sensors for jam detection upstream and downstream of the machine

- Secure and sturdy mechanical system

Drive

- Torque controlled shut-off via sliding clutch, magnetic coupling or servo

- Screw spindle with adjustable speed

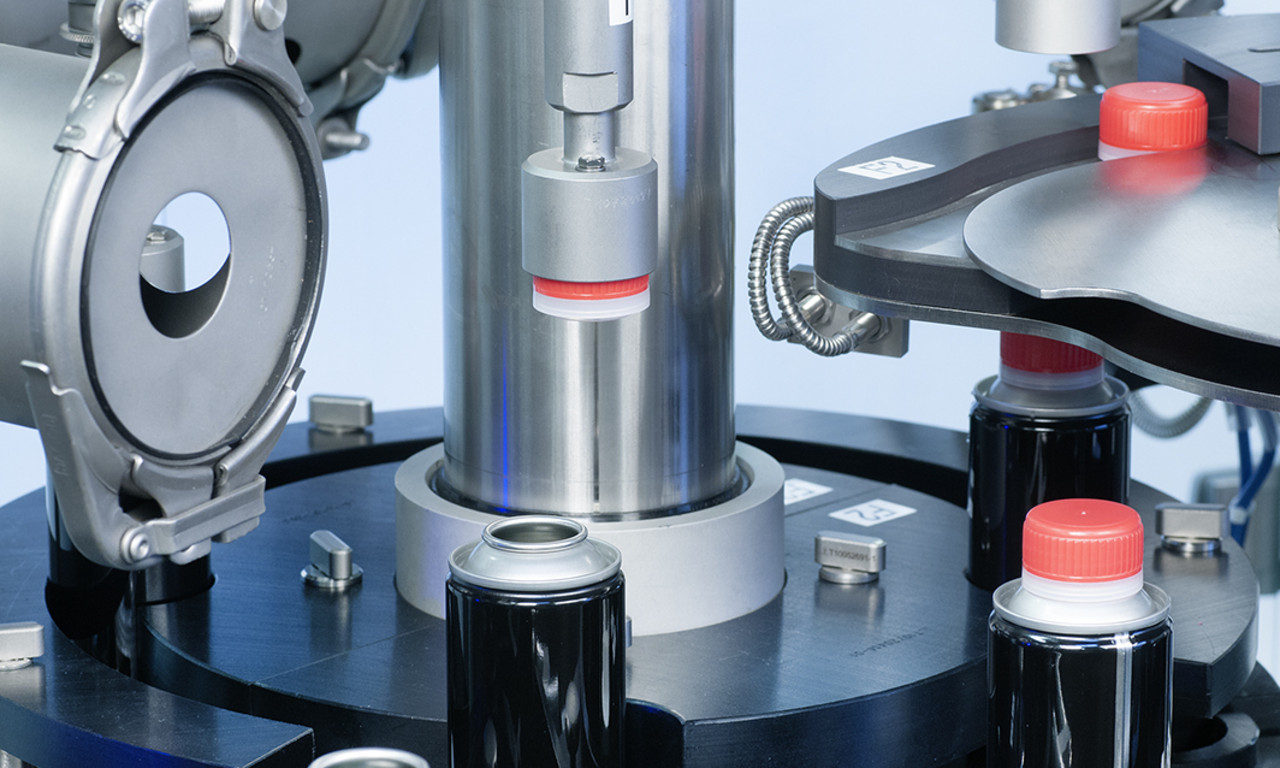

Manufacture/Closing

- Simple integration into existing packaging technologies

- Processing all standard types of caps

Cleaning

- Hygienic design for reliable production and easy cleaning

Handling

- Simple, clearly arranged operation and graphic display of the machine status on the HMI

Transport

- No carry-over due to the transport system if the container is leaking or cleaning the system with liquids

- Return conveyor for empty pucks

- Conveyor chains in stainless steel or anti-static plastic are optional

Quality Management

- Diverse monitoring functions using sensors or camera systems for quality assurance is optional

- Quality assurance via suitable monitoring functions

Technical details

- Output: between 120 containers/min and 600 containers/min

- Format change time: max. 20 minutes

- Basic measurements approx. (LxWxH): 1,750 mm x 2,380 mm x 24,800 mm

- Format range: max. 400 mm x 250 mm x 440 mm

- Working stations: between 4 screw spindles and 16 screw spindles